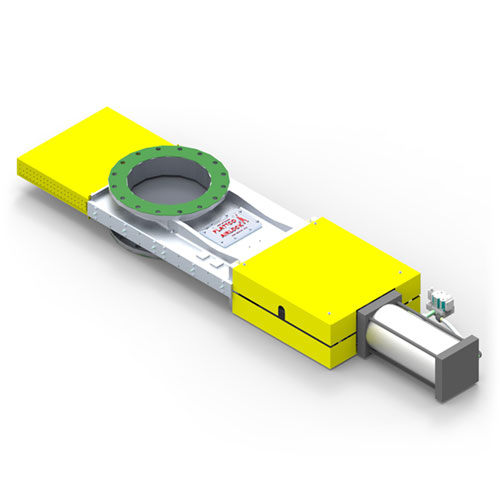

Plattco is pleased to offer our newest innovation, our HP slide gate valve, a high performance and high sealing slide gate valve specially designed for the cement industry to function as a diverter valve in critical pneumatic transport systems. The HP series slide gate valve is designed to handle abrasive dry powder materials at pressures up to 50 PSIG, making it the ideal pressure or vacuum pneumatic conveying line shutoff valve.

Designed for your system, these valves feature a unique wedge seal design which ensures a tight seal across the closed seat and flapper disk. The wedge design also allows for automatic wear compensation to ensure valve reliability. The access covers make this valve fully repairable in-line, facilitating inspections and predictive maintenance.

Our patented design is an industry first slide gate platform with sealing components adapted from double flap valve technology, ensuring a reliable long lasting seal across the valve when closed. Plattco gates use several different materials in its construction to achieve the best combination of functionality and value.

Plattco is pleased to offer our newest innovation, our HP slide gate valve, a high performance and high sealing slide gate valve specially designed for the cement industry to function as a diverter valve in critical pneumatic transport systems. The HP series slide gate valve is designed to handle abrasive dry powder materials at pressures up to 50 PSIG, making it the ideal pressure or vacuum pneumatic conveying line shutoff valve.

Designed for your system, these valves feature a unique wedge seal design which ensures a tight seal across the closed seat and flapper disk. The wedge design also allows for automatic wear compensation to ensure valve reliability. The access covers make this valve fully repairable in-line, facilitating inspections and predictive maintenance.

Our patented design is an industry first slide gate platform with sealing components adapted from double flap valve technology, ensuring a reliable long lasting seal across the valve when closed. Plattco gates use several different materials in its construction to achieve the best combination of functionality and value.

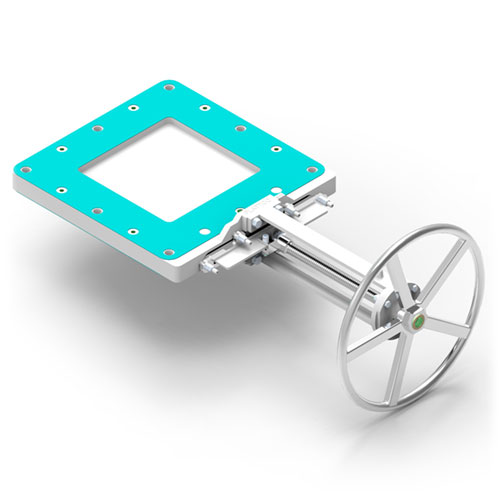

This is Plattco's low-profile slidegate valve. It is commonly used as a maintenance gate above a Plattco double flap airlock valve. It is meant for low cycling applications where headroom is limited.

Learn More

This is Plattco’s premium roller gate valve. This valve can be customized to fit nearly any installation footprint and application requirement. It is commonly used for gravity flow applications that require a reliable gate that won’t break the bank.

Learn More

This Plattco’s most economical roller gate valve. These valves are common in process critical applications – where operation of your plant depends on a reliable slidegate valve.

Learn More

A high performance and high sealing slide gate valve specially designed for the cement industry to function as a diverter valve in critical pneumatic transport systems. Ideal pressure or vacuum pneumatic conveying line shutoff valve.

Learn more

This is Plattco’s high temperature slidegate valve. This valve is designed to operate handling materials at extreme temperatures. Our proprietary design allows us to handle materials up to 1800F safely and reliably.

Learn More

IS Series – This is Plattco’s coal isolation gate valve invented specifically to act as the main fuel shut off valve to fluid bed boilers. Plattco invented the valve in the 1980s.

Learn More

This Plattco’s dry scubber discharge gate valve invented specifically for the energy industry. The unique design allows the valve to reliably operate as the discharge seal of a dry scrubber system.

Learn MorePlattco’s engineering and design team are able to collaboratively engineer a solution to meet your dry material handling needs based on your unique combination of application details and headroom available.

Learn More